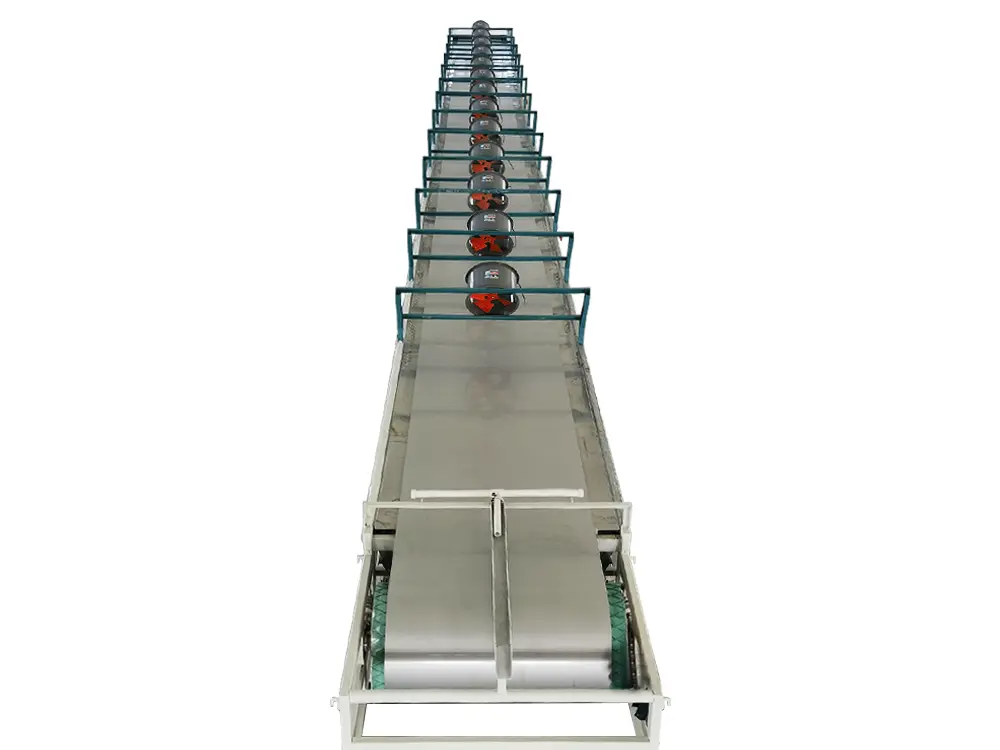

Automatic deskewing system

Category:

Keyword :

Automatic deskewing system

- Details

-

- Commodity name: Automatic deskewing system

Automatic deflection correction systems are essential in material handling. The sensor monitors the position of the material and sends a signal to the controller if there is any deviation.

Automatic Deskewing System

Automatic deflection correction systems are essential in material handling. The sensor monitors the position of the material and sends a signal to the controller if there is any deviation. The controller analyzes and directs the motor, hydraulic device and other actuators to drive the conveyor belt roller and other adjustments to the position, so that the material back to the correct track, to ensure accurate and stable conveying, to maintain the efficient operation of the production.

Enterprise Strength

The company insists on technological innovation, joining hands with Shandong University to form a top R&D alliance. We integrate cutting-edge technology and advanced technology to create customized aluminum sulfate automation equipment. Integrating high-precision control, high-efficiency material processing and intelligent monitoring, it precisely controls the production process and significantly improves the production capacity and quality. The advanced and stable technology demonstrates Dingheng's strength and innovation in the field of aluminum sulfate equipment manufacturing, and leads the industry in technological upgrading.

Shipping & Packaging

The core team members of the company are all from the backbone of the former state-owned Zibo Acid Factory. They have been working for a long time in the field of R&D and production of aluminum sulfate products and equipment, and have accumulated rich practical experience and developed superb professional and technical skills, occupying an important position in the industry.

Production video

Previous

Next

Yes, the full set of equipment is customized according to customer needs.

Under the standard working condition, it can produce 3~5 tons of high quality aluminum sulfate products per hour, and can ensure that all the indexes of the products are stable and reach the standard.

The main body of the equipment is made of high quality stainless steel, such as 316L stainless steel, which has excellent corrosion resistance and can operate stably in the strong acid environment of aluminum sulfate production for a long time, effectively prolonging the service life of the equipment.

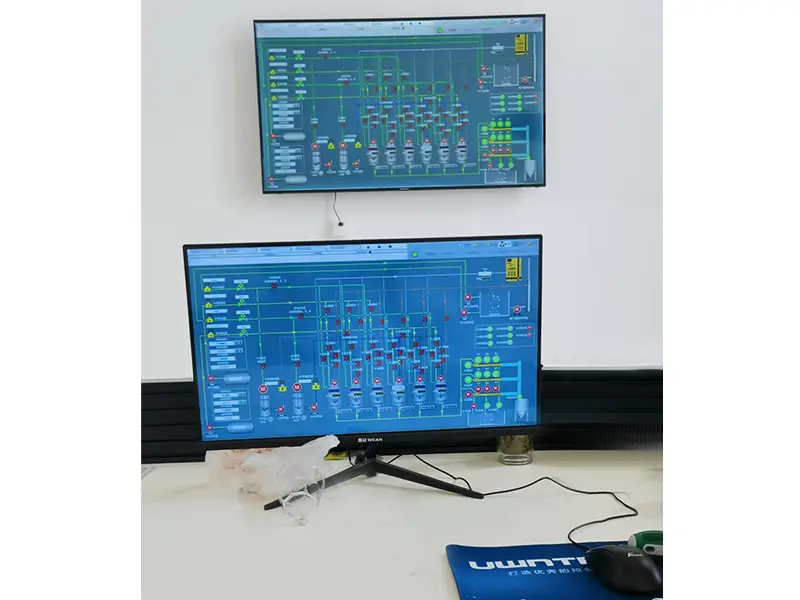

Our complete set of aluminum sulfate equipment has a high degree of automation. Equipped with advanced DCS/PLC control system, it can accurately and automatically control key parameters such as reaction temperature, pressure, etc., which reduces manual intervention, improves production stability and product quality consistency, and reduces safety accidents.

We have a professional installation and commissioning team, will be responsible for the door-to-door installation and commissioning of the equipment.

Equipment installation site needs to have a solid and level foundation, with good ventilation and perfect water and electricity supply facilities. The site area should be determined according to the specific model of the equipment and supporting facilities, we will provide detailed site planning program after the contract is signed.

Products

Aluminum Sulfate Steel Strips

-

Aluminum sulfate steel strip

The steel belt crystallizer is specially designed for the crystallization of aluminum sulfate and other chemical products.

-

Aluminum sulfate steel strip

It adopts the dual cooling mode combining air cooling and water cooling, which has good cooling effect, and the output is up to 3000 kg per hour.

-

Aluminum sulfate steel strip

It is equipped with advanced automatic deskewing system, which eliminates the need for manual deskewing and improves the accuracy and stability of production.

DCS Control System

-

DCS control system

In aluminum sulfate production, the operator station is the human-computer interface through which the operator precisely monitors parameters such as reaction temperature, pressure, flow rate, etc.

-

DCS control system

The DCS control system, as the intelligent center of distributed control, is a multi-technology system in which the operator station, the control station and the communication network work together

-

DCS control system

The DCS control system, as the intelligent center of distributed control, is a multi-technology system in which the operator station, the control station and the communication network work together

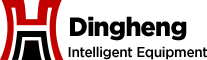

Pulverizer

Material Silo

-

Material Silo

The material silo is cylindrical, with the lower part tapering to a conical shape and a stopper. Corrosion-resistant and excellent strength, can bear the weight of materials and chemical erosion.

-

Material Silo

The material silo is cylindrical, with the lower part tapering to a conical shape and a stopper. Corrosion-resistant and excellent strength, can bear the weight of materials and chemical erosion.

-

Material Silo

The material silo is cylindrical, with the lower part tapering to a conical shape and a stopper. Corrosion-resistant and excellent strength, can bear the weight of materials and chemical erosion.

Baghouse Dust Collector

Aluminum Sulfate Reactor

-

Aluminum sulfate reactor

Aluminum sulfate reactor adopts glass-lined reactor. With strong acid resistance, it can resist the corrosion of aluminum sulfate solution and acidic substances, prolonging the service life of the reactor and reducing the maintenance cost.

-

Aluminum sulfate reactor

Good insulation can prevent safety accidents caused by static electricity and improve the safety of reaction. Smooth surface, smooth material flow, favorable reaction and subsequent cleaning, prevent residue and pollution, protect product quality.

-

Aluminum sulfate reactor

Good insulation can prevent safety accidents caused by static electricity and improve the safety of reaction. Smooth surface, smooth material flow, favorable reaction and subsequent cleaning, prevent residue and pollution, protect product quality.

-

Aluminum sulfate reactor

Good insulation can prevent safety accidents caused by static electricity and improve the safety of reaction. Smooth surface, smooth material flow, favorable reaction and subsequent cleaning, prevent residue and pollution, protect product quality.

Tail Gas Absorption Tower

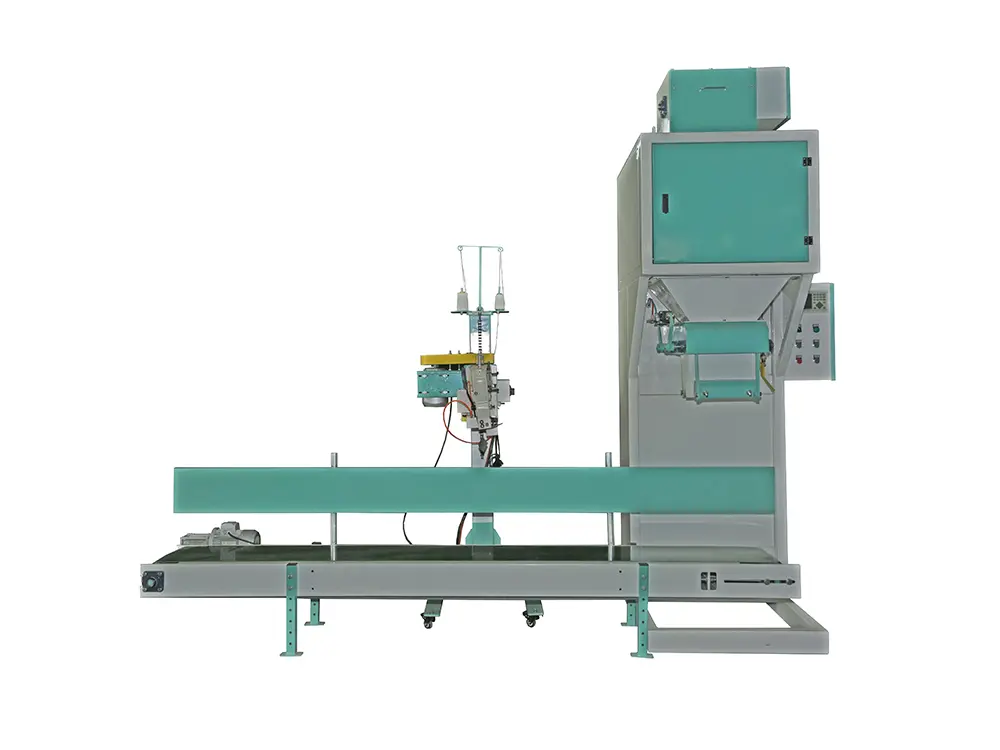

Conveyor Belt

-

Conveyor belt

This conveyor belt is made of high-strength polyester fiber as the core, which has strong tensile strength and can be used for long-time conveying of large capacity.

-

Conveyor belt

This conveyor belt is made of high-strength polyester fiber as the core, which has strong tensile strength and can be used for long-time conveying of large capacity.

-

Conveyor belt

This conveyor belt is made of high-strength polyester fiber as the core, which has strong tensile strength and can be used for long-time conveying of large capacity.

Automatic Deskewing System

-

Automatic deskewing system

Automatic deflection correction systems are essential in material handling. The sensor monitors the position of the material and sends a signal to the controller if there is any deviation.

-

Automatic deskewing system

Automatic deflection correction systems are essential in material handling. The sensor monitors the position of the material and sends a signal to the controller if there is any deviation.